The Lean Startup methods are hot; I’m talking, “You can’t touch this” hot, a la M.C. Hammer. At least that’s how it felt to me while attending last month’s Lean Startup Conference where more than 1,500 gathered to pay homage to Lean methods (Lean). It’s spreading like wildfire across the globe with workshops and follow-up books.

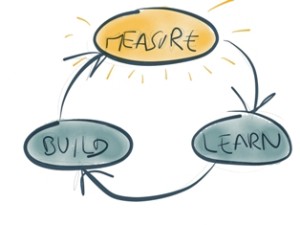

Lean methods are not off-base. I know a few entrepreneurs who have successfully launched using Lean. If you aren’t familiar with Lean methods, they were originally attributed to Toyota for its manufacturing process to eliminate waste and build only what the customer wants. Professor and entrepreneur Steve Blank smartly applied Toyota’s ideas to start-ups. Then, Blank’s student, Eric Ries built upon his ideas from his own experiences and wrote the bestselling book The Lean Startup because the ideas worked so brilliantly. Much of the basis for Lean is rapidly validating or invalidating assumptions you made about your proposed business model by interviewing people and collecting data. Lean advocates for rapid prototyping and market testing.

Lean methods are not off-base. I know a few entrepreneurs who have successfully launched using Lean. If you aren’t familiar with Lean methods, they were originally attributed to Toyota for its manufacturing process to eliminate waste and build only what the customer wants. Professor and entrepreneur Steve Blank smartly applied Toyota’s ideas to start-ups. Then, Blank’s student, Eric Ries built upon his ideas from his own experiences and wrote the bestselling book The Lean Startup because the ideas worked so brilliantly. Much of the basis for Lean is rapidly validating or invalidating assumptions you made about your proposed business model by interviewing people and collecting data. Lean advocates for rapid prototyping and market testing.

But what rubs me wrong is the intimation that any process other than Lean is waaaaay off-base. For example, an attendee at the Lean Startup Conference who runs a university entrepreneurship center said to a group: “If university entrepreneurial centers aren’t deploying Lean methods, I’m to the point of calling it malpractice.” Malpractice? Really? For something as artful as starting an innovative company?

One speaker was explaining that if you don’t receive positive feedback during your first interviews, then you should pivot and try other business models. But when I told him that upon starting my own business, First Research I didn’t pivot (despite some less than stellar feedback) but instead stuck with my original plan until I landed paying customers, his response was that I was “perhaps lucky” and that I probably did pivot as I went along. (Partially true; I tweaked and improved my approaches.) He said Lean would have improved my chances of success. But would it have?

Please don’t misunderstand me. Lean is terrific, and if you’re starting a business, you should become aware of its methods and read Eric’s book. But there are Achilles’ heels you should also be aware of. Here are a few:

- Customers are not visionaries: Lean heavily relies upon asking potential customers what they really want, and then changing based upon their feedback. Yet Steve Jobs famously said, “We built [the Mac] for ourselves. We were the group of people who were going to judge whether it was great or not. We weren’t going to go out and do market research. We just wanted to build the best thing we could build.”[i] Jobs isn’t alone. Henry Ford once said, “If I had asked people what they wanted, they would have said faster horses.” The best-of-the-best entrepreneurs are visionaries and have good insight (or instinct) into what business models will work and which ones won’t. This is the “sixth sense” for business. So sometimes good ideas require your own intuition (not a future customer’s intuition) and most of all, the persistence to see them through to success.

- Giving up too soon may be a mistake: Lean relies upon “rapid” discovery and avoiding pouring good time and money after bad ideas. Yet the truth about when to give up on your idea or aspects of your business model may rest somewhere in between. Sometimes persistence is the trait that makes founders successful, and I can validate that from my own startup experiences. The key is knowing the difference between when your idea is a good one…despite poor feedback…versus when you should punt because the idea simply won’t work.

- “Early adopter” customers are hard to find: Lean heavily relies upon conversations to validate or invalidate your assumptions. But “early adopters” or “innovators”– those who are quick to try a new idea– are rare. Some studies show that only 2.5 percent of people fit into this category. So when you try interviewing the other 97.5 percent, how capable are they of validating your assumptions? Often times, you have to educate the market that it has a problem and that your product will fix it. This process requires lots of time and finding a few early adopters who are willing to be on the leading edge of change.

- There are no set formulas for starting a business: Many aspects of Lean rely upon data accumulation and scientific-type methods. Yet start-ups are more like art projects than science experiments; they are fluid, and each one is created subtly or profoundly different from another. Any founder must apply multiple experiences and thought processes to make it successful. Lean methods are good, but so are other strategies such as persistence or releasing a finished product.

- You’ll learn the most from your early selling efforts: Lean advocates for lots of interviews and conversations before you invest much money into a prototype. This is a fine idea, but you can only learn so much from talking to people because, as I’ve discovered, each person will say something completely different from another. Maybe I’m old-school, but the best way to learn is through trying to sell your product or idea. When you ask for people’s money, that’s when you get true objections and honest feedback.

At the conference, an executive form GE articulated how Lean greatly improved the speed and efficiency by which that company introduces new products. I have no doubt. But what’s good for GE may or may not be good for you if you’re starting your own business. There are many ways to go about it. I’m not saying that Lean isn’t a good way to build a start-up… but it definitely isn’t the only way. And while Lean may be hot, it can be touched. Stop. Hammertime. Oh. Oh-oh. Oh. Oh.

[i] “Playboy Interview: Steve Jobs, by David Sheff, Playboy,” Longform.org, August 28, 2015, http://longform.org/stories/playboy-interview-steve-jobs

Sign up to get more great insights directly to your inbox.

As a special bonus, you'll also immediately get access to my inside analysis of what made 172 diverse companies achieve take-off revenue growth.